What is the function of printed circuit boards for boilers?

Printed circuit boards, also known as PCBs, play an integral role in heating systems and boiler units. It serves as the nerve centre for the unit, controlling the function of many different parts. This is both proactive and reactive, as it responds to internal and external conditions, as well as implementing commands entered through the display. In this post, we break down exactly how the PCB functions and why this is an important boiler part.

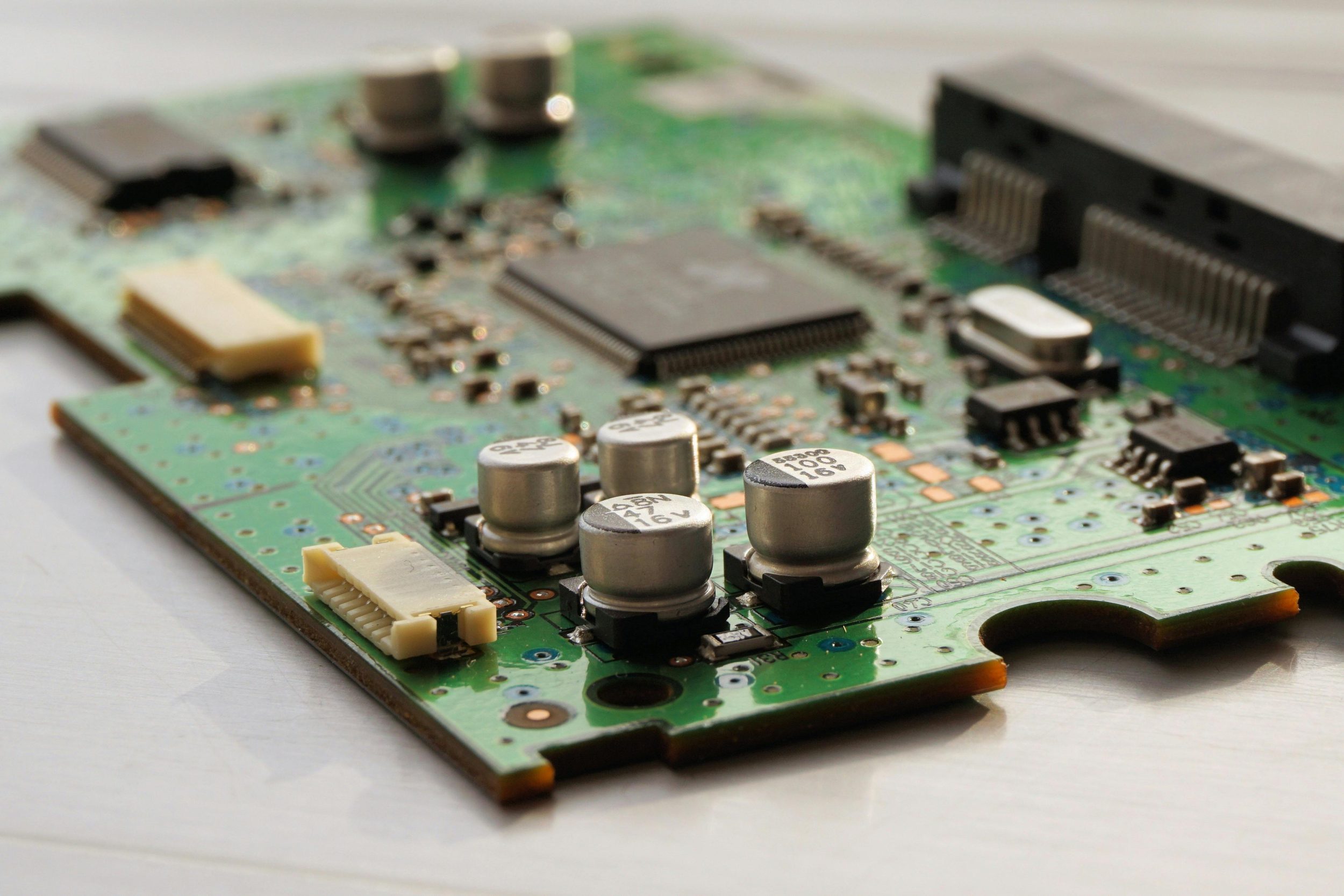

What is a boiler PCB?

A PCB is an assembly featuring layers of copper encased in an insulating material. A solder layer is then included as the outermost layer, which is where electrical components can be mounted. The exact layout of the PCB will depend on the make and/or model or boiler it is intended for use within. However, most will contain transistors, resistors, electrodes, and integrated circuits. If one of these components develops a fault it can warrant seeking out boiler PCB repair services, although more significant issues might require boiler PCB board replacement. Faults may develop over time as seals other components degrade. Learn more about how long a boiler PCB lasts.

The function of a PCB in a boiler

The primary role of a boiler PCB is to establish an electrical connection between various components. It monitors the signals sent and received by these parts of the system and in turn triggers actions when deemed necessary. Printed circuit boards see use in a variety of systems, including boilers and central heating networks.

Maintaining the functionality of the boiler PCB is essential for efficient heating within your home. You can find tips here on how to check if a boiler PCB is working.

As mentioned, PCBs in boilers serve as the central control unit. This means they are responsible for managing various functions such as temperature regulation, water flow, pressure monitoring, and safety features. They receive input from sensors throughout the boiler system and use programmed logic to control the operation of components like pumps, valves, and ignition systems.

Monitoring the status of the boiler is an essential function of the PCB as it triggers safety responses which are designed to prevent damage and potential harm. This can include shutdown procedures, activate alarms, and display error codes or warning messages to alert users to potential issues that require attention.

PCBs help optimise the efficiency of boiler systems by regulating the operation of components based on real-time data and user settings. They can adjust parameters such as fuel consumption, water flow rates, and ignition timing to minimise energy waste and maximise performance.

Many boiler PCBs connect with user interfaces such as digital displays, touchscreens, or control panels. These interfaces allow users to set desired temperature levels, program schedules, adjust settings, and receive status updates or diagnostic information about the boiler’s operation.

Some advanced boiler systems feature PCBs with connectivity options that allow integration with external control systems, smart home platforms, or building management systems. This enables remote monitoring, control, and automation of the boiler system for enhanced convenience and efficiency.

New and refurbished boiler PCBs available online

In conclusion, printed circuit boards are essential components in modern boiler systems. Without one that works as it should, your home heating and hot water system could be losing efficiency. National Boiler Spares stock parts for all the major boiler brands to meet any needs for boiler PCB repair. This includes the likes of Vaillant, Worcester, Ideal, Glowworm, Potterton, and more. Contact us if you have any questions regarding parts, delivery, or anything you’re unsure of.